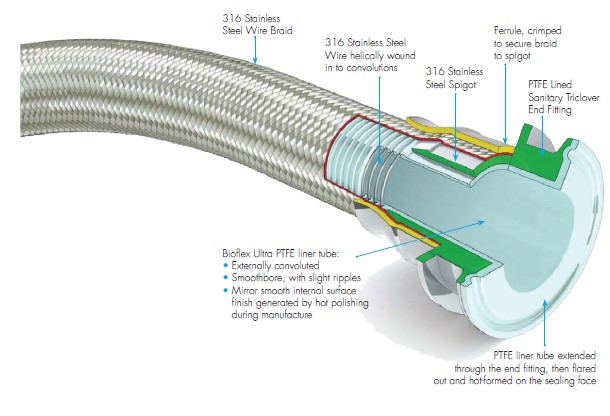

The key feature of the Bioflex hose is the PTFE liner design. The liner is comprised of integral rib sections which support the tube against kinking, vacuum and pressure. It also has highly compressed web sections which give a smooth-bore inner surface and excellent flexibility.

In 2013, in response to customer’s requests for an even more flexible and kink resistant hose, Aflex has re-designed the convolution profile of the Bioflex PTFE liner tube and introduced a high tensile, 316 stainless steel wire which is helically wound into the root of the convolutions. This wire provides greatly increased kink resistance by providing radial reinforcement to the tube, and axial reinforcement to the web section. This prevents the web section collapsing when the tube is heavily flexed.

The actual bore size of the tube and hoses has also been slightly increased to allow for easier insertion of fittings. Hoses incorporating this PTFE liner tube design have been re-named Bioflex Ultra.

The primary reason for the success of Aflex is that they are the only PTFE hose company in the world who perform the entire hose design and manufacturing process in house. Aflex’s hose manufacturing plants in Yorkshire (UK) and Pennsylvania (USA) carry out the entire process from raw materials through the finished product.

• PTFE powder is extruded into tube and convoluted.

• Stainless steel wire is wound and braided onto the tube.

• Rubber extruders are used to apply external covers.

• End fittings are machined from bar stock on state of the art CNC lathes.

• Finally, we here at PharmEquip assemble the hose to the customer’s specific requirements.

Because Aflex Hose perform all of these operations in house, they are able to achieve unbeatable levels of build quality, design excellence and economy of scale, which are unmatched by their competitors.

Bioflex Ultra Hose Grades are made up by combining the Design Options, which are defined by 2 letters as shown below, and fully described on the indicated pages.

For example, “Bioflex Ultra AS PB SG” defines a hose with an Antistatic PTFE liner (AS) and a Polypropylene braid (PB) and an outer “Safegard” (SG) spiral HDPE protection sleeve.

PTFE Liner Tube Options GP (Natural PTFE) and AS (Anti-static PTFE)

Braid Options TO (Tube Only, No Braid), SS (316 SS Wire), and PB (Polypropylene)

Rubber Cover Options RC (Blue EPDM), BK (Black EPDM) and SI (Silicone Rubber)

External Protection Options SR (Scuff Rings), SG (Safegard Spiral) and PC (SS Wire Coil)

Bioflex Ultra in Comparison with Convoluted PTFE Hose

• Hygienic Cleanability – much better, due to no internal convolutions

• Flow Rates – more than 2 x higher

• Pressure Ratings – more than 1.5 x higher

• Self Draining – 100% self draining with PTFE lined fittings

• Non-Whistling – no whistling noise with gasses

Bioflex Ultra in Comparison with Conventional Smoothbore FEP, PFA or PTFE Lined Rubber Hose

• No Adhesives – no toxic adhesives used in the Bioflex Ultra construction, eliminating the possibilities of Process Fluid contamination in service

• Flexibility – much better flexibility

• Internal Shape Control – no distortions in bore when flexed

Bioflex Ultra in Comparison with Silicone Rubber Hose

• Hygienic Cleanability – much better, due to the non-stick PTFE Liner

• Chemical Resistance – considerably improved, particularly to strong oxidising acids and bases

• Temperature & Pressure Ratings – much higher temperature and pressure capability

• Steam Resistance – permanently resistant to steam sterilising (unlike silicone hose, which has a limited life)

Pharmaline

For the most rugged applications where the hose may be subjected to rough treatment and severe external abrasion. Also for hygienic applications, where the external smoothness and clean-ability of the hose is of prime importance.

Maximum Working Pressure (MWP) Variation with Temperature.

MWP for SS grade hose, also for RC, BK and SI grades are as given in the graph, BUT only within the temperature range for the particular grade of hose, as given below:

Min/Max Operating Temperatures

Bioflex Ultra GP or AS SS -73oC to +260oC

Bioflex Ultra GP or AS SS RC & SS BK -40oC to +150oC

Bioflex Ultra GP or AS SS SI -73oC to +204oC

Bioflex Ultra GP or AS PB – MWPs for PB are as given in the graph up to 80oC, then reduced by 50% between 80oC and 100oC (the maximum for PB).

In practice, flow rates will vary with hose flexing, fluid viscosity, end fitting design and other parameters, but Bioflex Ultra hose flow rates are always around 2 times better than convoluted PTFE hose, when comparing hose assemblies with PTFE lined (non bore-restricted) end fittings.

Bioflex Ultra Hose – Flow Rate Calculation

If it is required to determine the flow rate of a particular hose assembly, or if it is required to determine the pressure required to generate a certain flow rate, then this can sometimes be approximately calculated by the Bioflex Ultra supplier.

It should be noted that calculations can only be made for fluids with a viscosity equal to water, and for hose assemblies with PTFE lined end fittings (no bore restrictions at the ends of the hose).

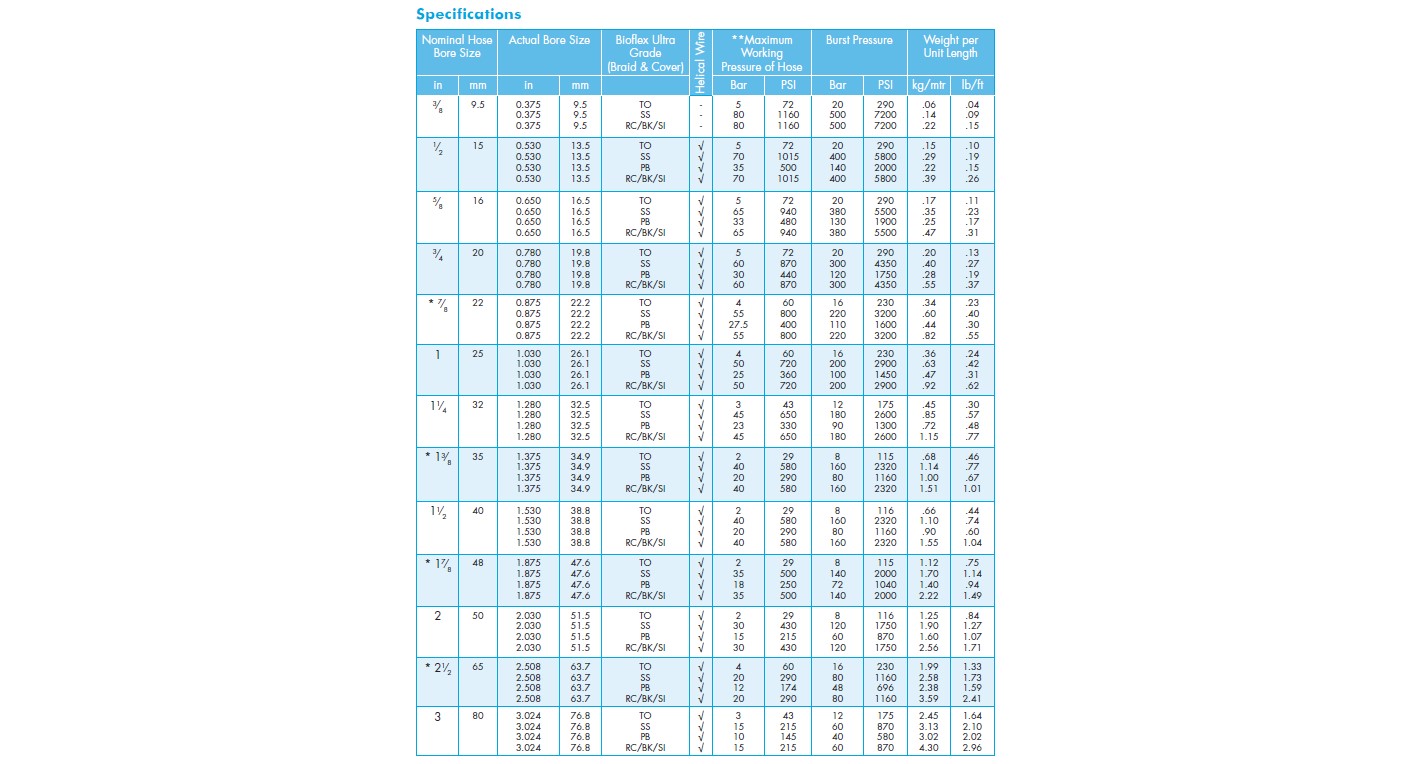

* Maximum Working Pressures vary with temperature as in graph below

** These sizes will be revised from 1st september to have slighty larger actual bore and OD dimensions, and to have a helix wire

Please contact our sales team if you would like any more information, or to place an order.