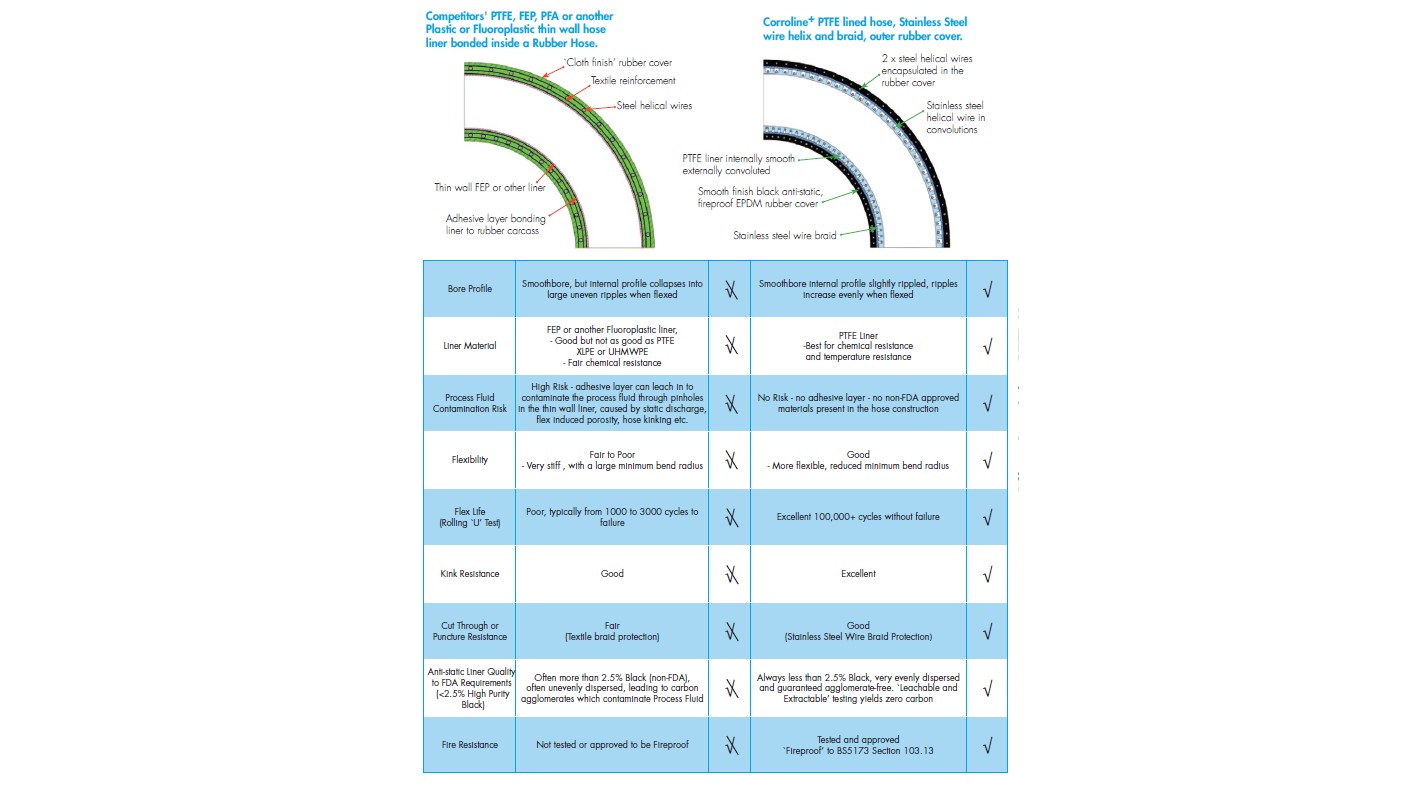

Corroline was originally developed and introduced by Aflex Hose Ltd in 2008. It was specifically designed to provide customers with a new smooth bore, PTFE lined hose which has better flexibility than the other chemical hose products on the market.

More recently customers have asked whether Aflex could improve their product further by improving the kink resistance of the hose, while retaining the excellent flexibility.

Aflex Hose has since developed Corroline+, a new version of Corroline combining excellent flexibility with exceptional kink resistance.

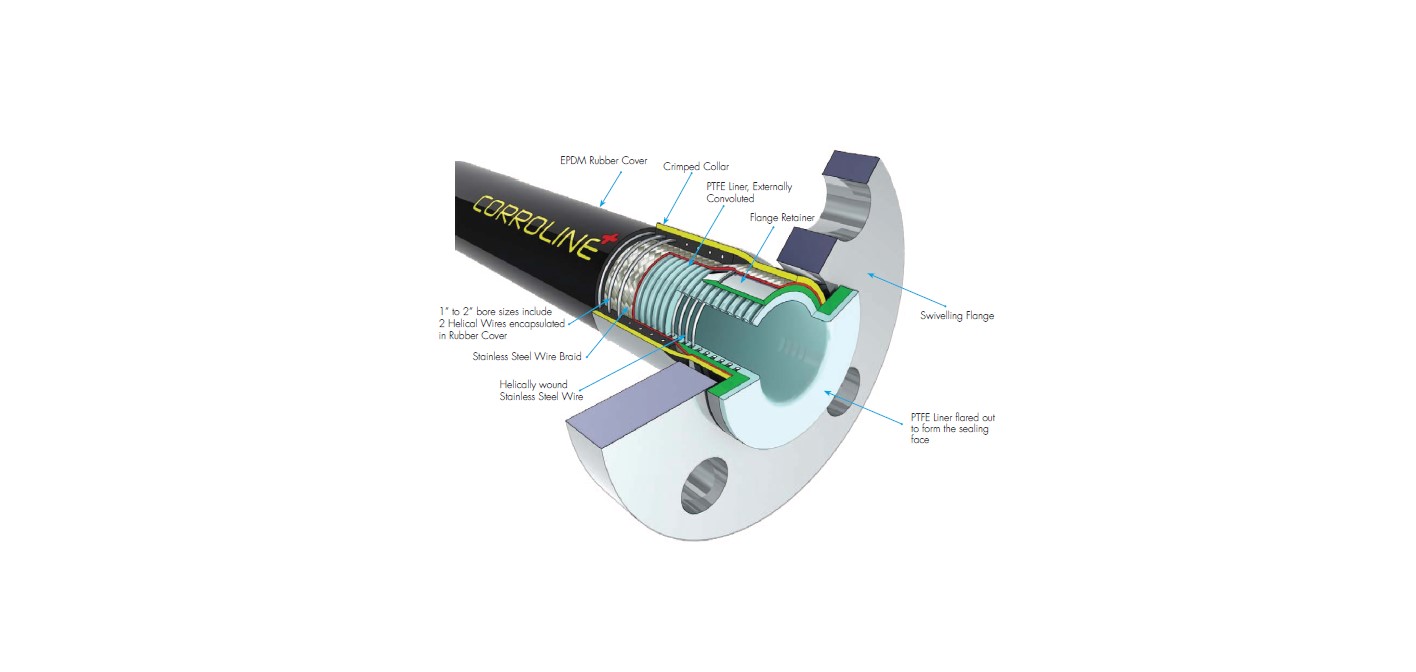

Corroline+ is built around a unique PTFE hose liner design, which has a slightly rippled smooth bore inside, but convoluted outside to generate excellent flexibility combined with “hoop strength”. Grade GP hose has a natural (clear) PTFE liner tube and Grade AS hose has an anti-static (Black) PTFE liner tube.

A stainless helical wire is wound in to the external convolutions, which adds to the kink resistance, crush resistance and the resistance of the hose to both pressure and vacuum.

This reinforced PTFE Liner construction is strong enough to withstand full vacuum and kinking without the need for either internal convolutions or the need to bond the liner to an outer cover, making it an ideal hose liner design, and a significant improvement upon standard products currently available.

The PTFE liner is then further reinforced with a 304 SS wire braid. A smooth finish black anti-static EPDM rubber cover is extruded over the braid, which includes two helical reinforcement wires encapsulated in the rubber cover which render the hose kink-proof. The rubber cover has a mirror smooth surface finish to aid cleaning, and the anti-static rubber is specially compounded to make the hose ‘fireproof’.

• Vacuum Limitations

Usable at full vacuum up to 140°C (284°F).

• Flexibility

Much less force to bend than any other smooth bore PTFE lined hose product.

• Kinkproof

Much more resistant to kinking than any other smooth bore PTFE lined hose product, and much more kink resistant than the previous Corroline product.

• Fire resistance

Corroline+ hose is Fireproof to BS5173 Section 103.13 Parts 6.2 and 6.3, and Corroline+ hose assemblies can be upgraded to Fireproof by applying DBK 300 at each end (see page 63). All assemblies comply with the flammability requirement as set out in BS.EN.12115.

• Rolling U Flex Life Test

More than 100 × the flex life to failure compared with all other types of smooth bore PTFE, FEP and PFA lined rubber covered hose products.

• Flow rates

More than 2 times the flow rates for convoluted bore hose designs. Consult PharmEquip for specific flow rate information.

• Gas permeability

Reduced gas permeability compared with other PTFE lined hose designs, due to the heavy compression applied to the PTFE during processing, which reduces porosity.

Pharmaline N or Bioflex Ultra

Corroline+ GP is the `General Purpose’ grade, for use in all applications where fluids or gases are being conveyed which do not generate a risk of static charge development (see `AS’).

Corroline+ GP is a virgin PTFE liner, manufactured from hose grade PTFE which conforms to the requirements of

FDA 21 CFR 177.1550.

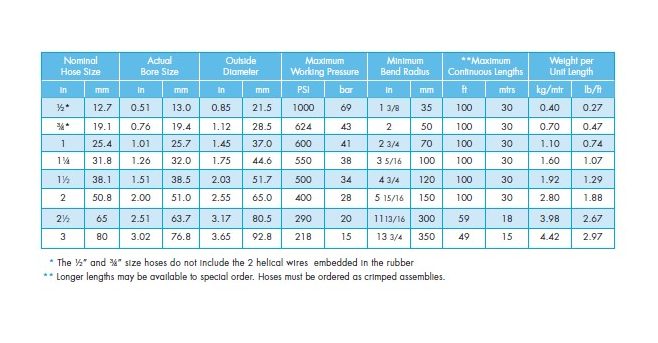

The helical reinforcement in the convolutions in the liner is High Tensile Grade 316 SS wire. The helical reinforcing wires embedded in the rubber cover are carbon steel wires. The specially compounded, black EPDM rubber cover is anti-static in accordance with EN ISO 8031 Annex A and the stainless steel braid is grade 304 SS.

Corroline+ AS is an essential requirement in applications where there is the risk of an electrostatic charge build-up on the inside surface of the PTFE tube which may then discharge through the tube wall. Media passing through which create such a risk are fluids which have a Conductance of less than 10-8 S/m (Siemens per Metre), or 104 pS/m such as fuels, solvents, freons, some WFI (ultra-pure `Water for Injection’) and non-polar organics which are being transferred at a medium to high flow velocity.

All twin or multi phase media, and any non-mixing media, such as powder in air, or water droplets in steam, in gases or in oil, also colloidal fluids constitute a particular hazard for static charge generation, and always require grade AS.

Corroline+ AS is an anti-static PTFE liner manufactured from FDA 21 CFR 177.1550 approved PTFE, and less than 2.5% of `high purity’ Carbon Black material to FDA requirement 21 CFR 178.3297 and European Commission Directive 2007/19/EC. The carbon is encapsulated by the PTFE, and in normal, non-abrasive applications will not come loose to contaminate any fluid passing through. This has been proved during Leachables and Extractables testing.

Maximum Working Pressures – as listed above apply from -40°C (-40°F) up to the maximum operating temperature of 140°C (284°F).

Burst Pressures – The hose burst pressures are equal to or more than the maximum working pressures × 4.

Please contact us if you have any questions, or would like to place an order.